Articles

Pioneering Precious Metal Recovery With Laser CleaningLike This

Like

The advent of laser cleaning technology has created a significant shift in the field of precious metal recovery. This sophisticated, eco-friendly, and highly efficient process promises an optimized recovery method that significantly outpaces traditional strategies.

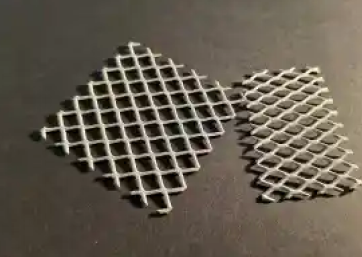

At the core of this cutting-edge technology is the use of lasers for cleaning surfaces coated with precious metals, such as anode mesh surfaces and anode filters. Notably, laser cleaning is highly effective on materials coated with precious metals such as Ruthenium and Iridium, vaporizing the coatings and leaving the underlying surfaces intact.

The primary advantage of laser cleaning is its precision. It targets only the desired areas, reducing the risk of damage to the surface beneath the precious metal coating. This is in stark contrast to grit blasting, a traditional method that can harm surfaces due to its abrasive nature.

Moreover, laser cleaning provides a more cost-effective and efficient process for precious metal recovery. When the laser ablates the metal coating, an extraction unit with a HEPA filter captures the vaporized precious metals. These filters can then be incinerated by a precious metal recovery specialist to extract a higher yield of precious metals than could be achieved through grit blasting

The grit blasting process, on the other hand, results in a mixture of blasted materials and precious metals. This mixture necessitates a complex and costly separation process to recover the precious metals.

Companies interested in adopting laser cleaning technology for precious metal recovery can target industries that frequently use precious metal coatings. These include manufacturers of semiconductors, catalysts, and medical and industrial coatings, among others.

When seeking potential partners or customers, companies can use search terms like “precious metal anodes,” “iridium and ruthenium coatings,” or “precious metal protective coatings” to find opportunities in their local markets.

As the demand for precious metals continues to grow, so too does the importance of efficient recovery methods. Laser cleaning technology is poised to revolutionize the precious metal recovery industry, offering a greener, safer, and more effective solution.

May 21, 2024

May 21, 2024